NDPM Series Horizontal Ribbon Mixer

General Description Specification: Configurations list DETAILED PHOTOS Simple Maintenance 1. Change gland packing once a year. 2. Add gear oil to the reducer nearly once a year. Factory Show Production and processing

General Description

NDPM series mixer with horizontal tank, single shaft with dual spiral symmetry circle structure. The top cover of the U-shape tank has the entrance for the material, it can be designed with spray or addliquid device according to customer鈥檚 needs. Inside the tank equipped the axes rotor which consists of cross support and spiral ribbon.

Under the bottom of the tank, there is a flap dome valve or butterfly valve of the center. The valve is arc design that ensure no material remains and without any dead corner during mixing. Reliable seal prohibits the leakage between frequent open and close.

The discon-nexion ribbon of the mixer can make the material mixed with more high speed and uniformity in shout time.

This mixer also can be designed with the function to keep cold or heat. Add one layer outside the tank and put into medium into the interlayer to get the mixing material cold or heat. Usually use water for cool and hot steam of use electrical for heat.

Specification for Ribbon Mixing machine:

Model | NDPM 100 | NDPM 200 | NDPM 300 | NDPM 500 | NDPM 1000 | NDPM 1500 | NDPM 2000 | NDPM 3000 | NDPM 5000 | NDPM 10000 |

Effective Volume | 100L | 200L | 300L | 500L | 1000L | 1500L | 2000L | 3000L | 5000L | 10000L |

Volume | 140L | 280L | 420L | 710L | 1420L | 1800L | 2400L | 4000L | 7100L | 14000L |

Turning Speed | 46rpm | 46rpm | 46rpm | 46rpm | 46rpm | 46rpm | 46rpm | 36rpm | ||

Overall Size(mm) | 1100x750x1300 | 1370x834x1647 | 1550x970x1655 | 1773x1100x1855 | 2394x1320x2187 | 2715x1397x2313 | 3080*1625*2453 | 4270*2200*2400 | 4400*1500*1750 | 5515*1768*2400 |

| Radius of Barrel(mm) | 210 | 277 | 307 | 377 | 450 | 485 | 534 | 133 | ||

Total Power | 3KW | 4KW | 5.5KW | 7.5KW | 11KW | 15 KW | 22 KW | 22kW | 45kW | 75kW |

Power Supply | 3 phase 208-415v 50/60HZ | |||||||||

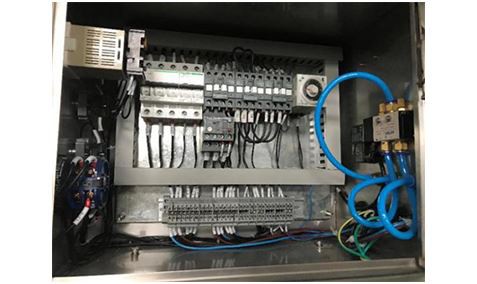

Configurations list

NO. | Name | Brand |

1 | Stainless steel | China |

2 | Circuit breaker | Schneider |

3 | Emergency switch | Schneider |

4 | Switch | Schneider |

5 | Contactor | Schneider |

6 | Assist contactor | Schneider |

7 | Heat relay | Omron |

8 | Relay | Omron |

9 | Timer relay | Omron |

DETAILED PHOTOS

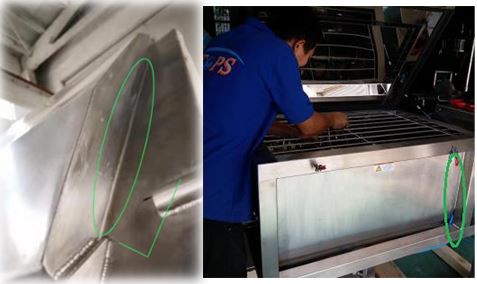

1. The whole welding place of the machine are full welding, including the ribbon, the frame, the tank, etc. Especially for the lid of the barrel, the full welding technology makes sure there is no gap to hide material |

|

| 2. The round corner design of the lid, makes it more safety when it is open. And the silicon ring makes it is much easier to maintain and clean. |

3. Safety device to avoid the personal injury, auto stop when mixing tank lid is opened. |

|

| 4. Good quality of pneumatic control system, resistance of abrasion, prolong its life |

5. Mirror polished inside of the tank, no dead area, and easy to clean. |

|

| 6. Electrical parts, Relays, contactors are world famous brands, to guarantee the work stability of the mixer. |

7. Safety grid to avoid personnel injury. |

|

| 8. Can equip with spray system & double jacket cooling and heating function |

Simple Maintenance

1. Change gland packing once a year.

2. Add gear oil to the reducer nearly once a year.

Factory Show

Production and processing

Hot Tags: NDPM Series Horizontal Ribbon Mixer, Ribbon Mixing聽machine, Ribbon Blender Mixing, mixer machine, ribbon mixer machine, manufacturers, suppliers, used, for sale,