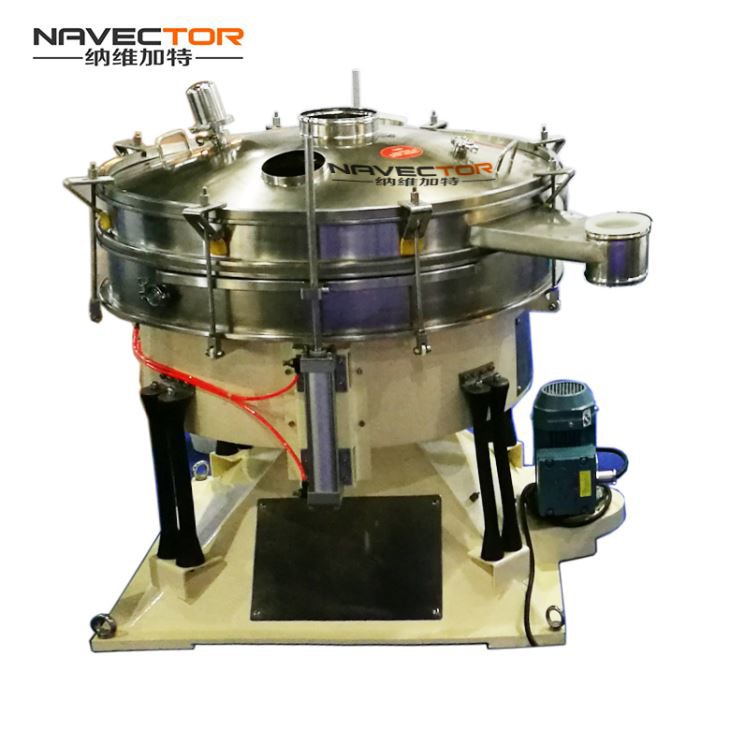

Flour Tumbler Screening Machine

To achieve the most requesting need of fined and ultra fined screening of material we as a manufacturer, supplier and exporter of screening machine do high thickness sieving proficient Tumbler screen at the prudent rate in the allied market.

Product Description

To achieve the most requesting need of fined and ultra fined screening of material we as a manufacturer, supplier and exporter of screening machine do high thickness sieving proficient Tumbler screen at the prudent rate in the allied market. Our tumbler screen is a best case of the innovation headway in the screening which executes the best with a wide range of fined and ultra fined powders, and granular materials which are hard to isolate by sieving. Tumbler screening is an extemporized system to the next screening methods where item on the screen is moved from the middle by outspread tendency while the unrelated tendency prompts round movement of the item. Along these lines, tumbler screening gives min. 90% screening proficiency with delicate screening of sensitive particles to forestall molecule annihilation.

Structure principle

1. The basic rotational motion is similar to that of artificial screening. The eccentricity can be adjusted from 20 to 40 mm, and low speed V type belt driven is adjustable from 120 to 360 rpm.

2. The residence time of each product can be adjusted by the radial and chamfer angle of the swinging screen.

3. The material forms horizontal and throwing 3D roll motion and evenly disperses from the center to the edge of the sieve surface, thereby axial propagation in a helical motion. Thus fine particles complete the entire screening process.

4. The horizontal and vertical acceleration increases with the movement of materials, and the particles close to the aperture size are successfully separated; large particles are moved to the exit, where has an adjustable steering device to control the flow, which is another factor that controls the retention time of the material.

5. The process is repeated between each sieve layer.

Mesh cleaning: Silicone bouncing balls, Rolling brush and Ultrasonic system

Tumbler Screening Machine Data Sheet

Feed Sizes | 20 Ојm вҖ“ 20 mm |

Feed Rates | 1 kg/h вҖ“ 50.000 kg/h |

Bulk Densities | 20 вҖ“ 10.000 g/l |

Mesh Openings | 20 Ојm вҖ“ 20 mm |

Screens Usable | Stainless steel wire or perforated plates |

No. of Decks | 1 вҖ“ 5 |

Mesh Cleaning | Jumping balls/rings, Rotating brush, Ultrasound |

Speed Range | 180 вҖ“ 280 minвҖ“1 |

Screen Movement | 3-dimensional, settable |

Acceleration | 1.3 вҖ“ 1.8 g / 60 вҖ“ 80 mm horizontal & 5 вҖ“ 40 mm vertical |

Materials | Carbon steel, stainless steels 304/316 |

Machine Surface Treatment | Painted, brushed or mirror polished |

Tumbler Screener Parameters

MODEL SIZE | NTS1200 | NTS1500 | NTS1800 |

Screening area (mВІ) | 1.13 | 1.76 | 2.54 |

Diameter (mm) Гҳ | 1200 | 1500 | 1800 |

Motor power (kW) | 1.1KW | 4KW | 4KW |

Weight (kg): | 930вҖ“1120 | 1080вҖ“1450 | 1250-1760 |

A(mm) | 1236 | 1457 | 1500 |

B(mm) | 904 | 1132 | 1132 |

C(mm) | 757 | 950 | 950 |

D(mm) | ПҶ250 | ПҶ250 | ПҶ300 |

E(mm) | ПҶ200 | ПҶ200 | ПҶ300 |

F(mm) | ПҶ200 | ПҶ200 | ПҶ300 |

G(mm) | 1574 | 1940 | 2334 |

K(mm) | 1210 | 1517 | 1817 |

W(mm) | 1040 | 1122 | 1400 |

L(mm) | 1040 | 1122 | 1400 |

Layers Available | 5 | 5 | 5 |

Flour Tumbler Screening Machine Manufacturer |  Flour Tumbler Screening Machine Suppliers |

Options:

ATEX version

Use in a potentially explosive plant environment.

Bouncing ball cleaning

Use with grainy products. There are balls located between one perforated floor and the screen fabric, which strike the screen fabric from below.

Brush cleaning

Use with crystalline or spherical products. Rotation under the screen.

Ultrasonic cleaning

Use in the ultrafine mesh range. The ultrasound is input into the screen using resonators.

Air cleaning

Use with sticky products. Air blowing out of rotating nozzle arms clears the screen fabric.

Lifting devices

Quicker access to the screening inserts.

Hygienic design

Machines are available with a high-quality "pharmaceutical finish".

Air brush cleaning

Use with greasy or electrostatically charged products.

Special outlets

Individual adaptation to upstream or downstream machinery.

Hot Tags: flour tumbler screening machine, manufacturers, suppliers, used, for sale,