Vibro Screen

The principle of Vibro Screen is transmitted in a pair of unbalancing weights, an upper weight installed on the shaft upper of a motor and the other weight on the shaft lower, which are capable of converting the motor rotation into a three-dimensional motion including horizontal, vertical and inclination vibration of screen...

1. Vibratory Sieve Introduction

1) Principle

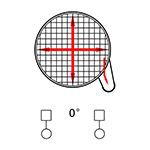

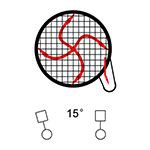

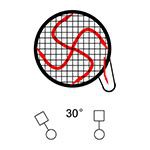

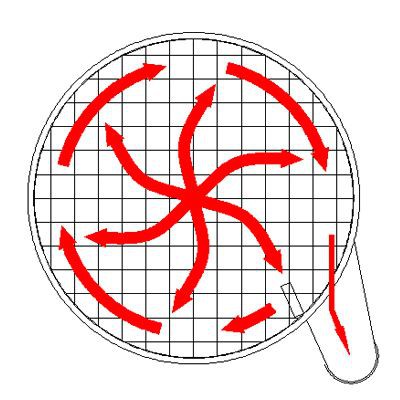

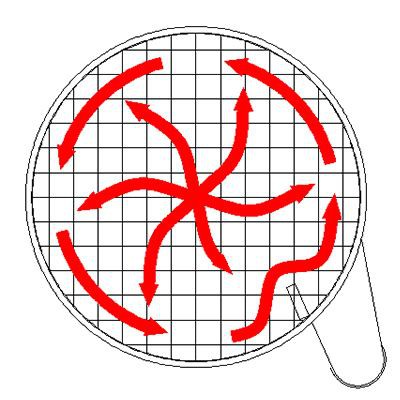

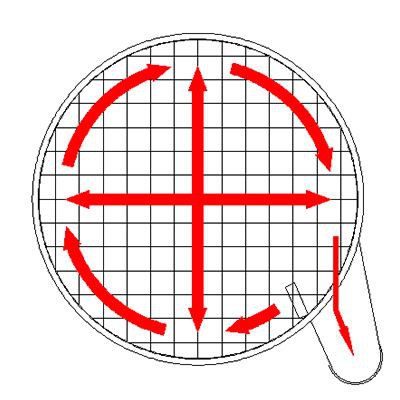

The principle of Vibro Screen is transmitted in a pair of unbalancing weights, an upper weight installed on the shaft upper of a motor and the other weight on the shaft lower, which are capable of converting the motor rotation into a three-dimensional motion including horizontal, vertical and inclination vibration of screen. By controlling the phase-angels of those weights before operation, they provide several type of grain flow.

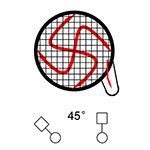

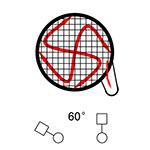

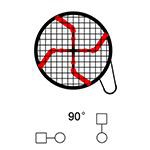

2) Vibratory Separator Features

|  |  |  |  |  |

Grains flow straightly from center to circumference. Easily screenable grains, speedy sieving of coarse grains. | Slight vortex motion. Ordinary screening | Deeper vortex. Enhance the screening effect. | The vortex is further lengthened and can be used for precision screening | The Deepest vortex to achieve the highest and mos teffective screening material of pulverlized grains, high condensasion or high moisture | Grains concentrated towards center. Prevent large material from popping up |

3) Our Industrial Vibrating Sieve Range Include:

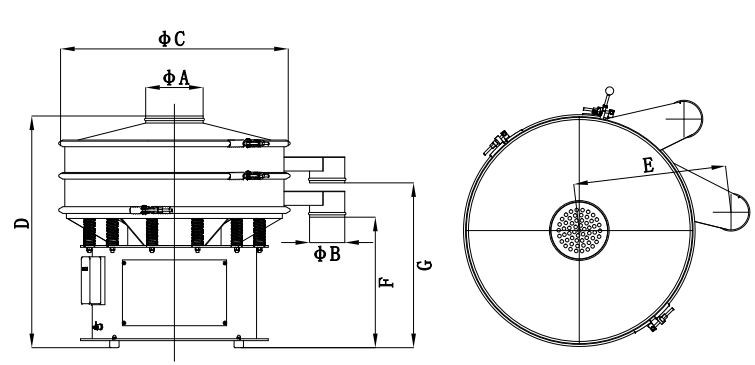

4) Vibro Separator Specification

Type | 400 | 600 | 800 | 1000 | 1200 | 1500 |

A | 145 | 145 | 195 | 245 | 245 | 245 |

B | 100 | 100 | 100 | 150 | 170 | 200 |

C | 400 | 600 | 800 | 970 | 1170 | 1470 |

D | 700 | 900 | 940 | 990 | 1075 | 1200 |

E | 302 | 442 | 557 | 651 | 780 | 938 |

F | 370 | 480 | 505 | 555 | 610 | 675 |

G | 524 | 630 | 655 | 705 | 760 | 840 |

Power(KW) | 0.2 | 0.35 | 0.6 | 1.1 | 1.1 | 1.5 |

Excitation Force(KN) | 4 | 7 | 13 | 20 | 20 | 32 |

2. Vibrating Sieve Attachable functions

1) Reverse type

a) Introduction

Reverse revolution during screening aims at perfect screening

The materials in the machine are screened, usually moving clockwise toward the discharge opening, The reverse function switches the material movement between screening(counter-clockwise) and discharging (clockwise) the materials, and repeats the reversals to realize nearly perfect screening /discharge with efficiency exceeding 95%.

This can meet the powder industry's demand for finer particles.

CLASSIFICATION/DIACHARGE AT MORE THAN 95% EFFICIENCY

Ordinary screening |  Screening(counter-clockwise) |  Discharging(clockwise) |

b) Video: Function of reverse screening

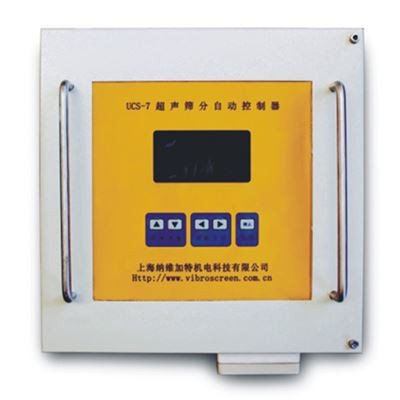

2) ULTRASONIC type

The Choice for fine particle separation. The ultrasonic anti-blinding action could increase throughtput by 50-100% compared to non-ultrasonic systems, in some applications, the increase is as much as 400%.

he Ultrasonic system enables separators to perform fine mesh screening (60-635mesh) on applications previously thought impossible. The system enhances screening by creating a low –amplitude, (4-6um) high frequency (36Khz) secondary vibration on screen surfaces, improving performance of fine mesh screening of both light and heavy density powders, and even particles carrying an electrostatic charge.

a1) Navector ultrasonic

в—Џ Power supply: 220vВ±10% (50/60hz), single-phase

в—Џ Maximum output: 60W (variable according to the load)

в—Џ Generating frequency: 35khz

в—Џ Generating mode: Continuous/pulse

в—Џ Outer dimensions:

a2) Ultrasonic screen P-type(Inner/outer)

|  |  |

b1) Artech Ultrasonic (Made in Swissпә‰

в—Џ Power supply: 220vВ±10% (50/60hz),single-phase

в—Џ Rated current: Maximum 1A

в—Џ Maximum output: 60W (variable according to the load)

в—Џ Generating frequency: 35khz

в—Џ Generating mode: Continuous/pulse/hopping operation

в—Џ Protection class: IP65

в—Џ Ultrasonic intensity: 20~100%

b2) Ultrasonic screen P-type(Inner/outer)

|  |  |

c) Video: How ultrasonic screening works

3. Vibro Screen Application

Silica carbide screening platform |  Pharmacy Vacuum conveying & screening |  NCM powder screening |

Aerospace material protective screening & storage |  Wheat flour screw conveyor & Screening |  Battery material Screening |

3D printing powders Storage & feeding & Screening system |  Metal powder:Argon Gas protective screening |

4. Vibro Screen Production Flow

Raw material purchasing |  Accessories purchasing |  Plate rolling and welding |

Accessories welding and Assembly |  Polishing |  Remshing-screen Assembly |

Preparation Before Assembly |  Final Assembly |  Appearance and Performance inspection |

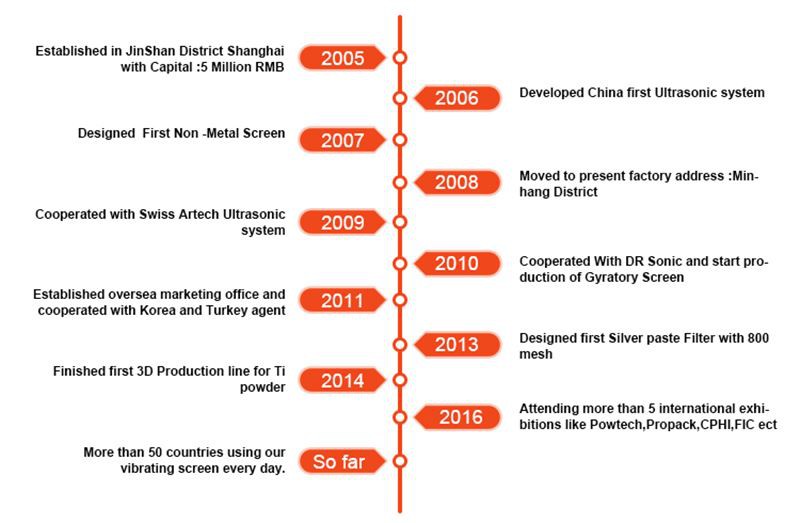

5. Company Introduction

Shanghai Navector established in JinShan district, specialized in Vibro Screen. We are not only designing and making sieving machines, but also providing comprehensive screening solutions. Committed to create a new screening concept, and leading technology and personalized quality experience is more important than the sieving machine itself.

1) The DevelOpment Process Of The Company

2) The Exhibition Scene

3) Certificates

Hot Tags: vibro screen, manufacturers, suppliers, used, for sale,