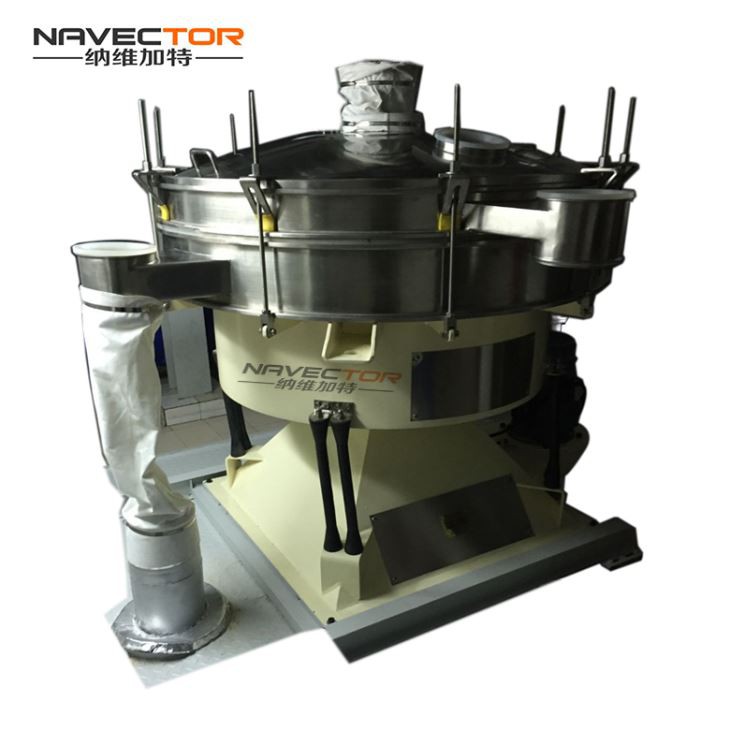

Lactose Tumbler Screening Machine

Layer: 1-5

Product type:Automatic

Diameter of screen(mm): 600-2600

Tumbler Screening Machines

Layer: 1-5

Product type:Automatic

Diameter of screen(mm): 600-2600

Sieving precision: вүӨ500 mesh or вүҘ0.028mm

Power(KW): 0.75-55

Custmoized service: All parts can be customized

Structure material option:316L stainless steel, 304 stainless steel, carbon steel

Price(USD): 4500-28000

Application: Powder, Granules, Liquid, Bulk Solids and other ingredients.

Product Introduction

The tumbler screener is a low-frequency vibro sieving machine that is artificially oscillating for fine and ultra-fine screening. Round, cylindrical, flake, or even irregularly shaped materials can be sifted with up to 7 grades of ultra-fine sieving.

The instantaneous motion of tumbler screener is the combination of the radial displacement and the circular motion with the displacement along the axis (spiral motion). The exciter that can adjust the eccentricity produces a nonlinear three-dimensional motion, and the material also produces the same approximate manual movement to achieve the purpose of screening, and the screening accessory can be used to obtain one more ideal sieving effect.

As the result, the tumbler screener can realize one perfect sieving solution with 99% accuracy and more than 5 times higher output than tradition vibration sieving mahines.

Application Industries: Powder, Granules, Bulk Solids, Liquid and other ingredients

(Materials below are just parts of our material list, for complete list, please consult us)

Chemical industry: resin pigment, medicine, grease, paint, palette, cosmetic, etc.

Food industry: sugar, salt, alkali, gourmet powder, starch, milk powder, yeast powder, pollen, food additive, bean milk, juice, etc.

Metallurgy industry: aluminum powder, lead powder, copper powder, ore, alloy powder ,electrode powder, manganese dioxide, electrolytic copper powder, electric magnetic material, polishing powder, refractory material, etc.

Mining industry: kaolin, alumina, carbon, quartz sand,titanium oxide, zinc oxide, etc.

Abrasive material and ceramic industry: building sand, mica, alumina, abrasive,refractory material, slurry, etc.

Mechanical industry: casting sand, powder metallurgy, electromagnetic material and metal powder, etc.

Paper-making industry: coated slurry, exhaust liquid, paper making liquid and waste water reclamation, etc.

Pollution treatment: waste oil, waste water,additives, activated carbon,etc.

Highlight of NAVECTOR Tumbler Screener

High Output and AccuracyвҖ”вҖ”The sieve radius of 600mm~2600mm and rotating speed of 120~360RPM

Artificial OscillationвҖ”вҖ”Using artificial sieving motion

Motors ProtectionвҖ”вҖ”Motors perfectly wrapped in copper wire

Unique body structureвҖ”вҖ”Unique design based on engineering science

Top 304 Stainless PlateвҖ”вҖ”Machine parts made by top 304 stainless panel

Low working soundвҖ”вҖ”Only 70~75 decibel of working sound

|  |

Tumbler Screening Machine Data Sheet

Feed Sizes | 20 Ојm вҖ“ 20 mm |

Feed Rates | 1 kg/h вҖ“ 50.000 kg/h |

Bulk Densities | 20 вҖ“ 10.000 g/l |

Mesh Openings | 20 Ојm вҖ“ 20 mm |

Screens Usable | Stainless steel wire or perforated plates |

No. of Decks | 1 вҖ“ 5 |

Mesh Cleaning | Jumping balls/rings, Rotating brush, Ultrasound |

Speed Range | 180 вҖ“ 280 minвҖ“1 |

Screen Movement | 3-dimensional, settable |

Acceleration | 1.3 вҖ“ 1.8 g / 60 вҖ“ 80 mm horizontal & 5 вҖ“ 40 mm vertical |

Materials | Carbon steel, stainless steels 304/316 |

Machine Surface Treatment | Painted, brushed or mirror polished |

Tumbler Screener Parameters

MODEL SIZE | NTS1200 | NTS1500 | NTS1800 |

Screening area (mВІ) | 1.13 | 1.76 | 2.54 |

Diameter (mm) Гҳ | 1200 | 1500 | 1800 |

Motor power (kW) | 1.1KW | 4KW | 4KW |

Weight (kg): | 930вҖ“1120 | 1080вҖ“1450 | 1250-1760 |

A(mm) | 1236 | 1457 | 1500 |

B(mm) | 904 | 1132 | 1132 |

C(mm) | 757 | 950 | 950 |

D(mm) | ПҶ250 | ПҶ250 | ПҶ300 |

E(mm) | ПҶ200 | ПҶ200 | ПҶ300 |

F(mm) | ПҶ200 | ПҶ200 | ПҶ300 |

G(mm) | 1574 | 1940 | 2334 |

K(mm) | 1210 | 1517 | 1817 |

W(mm) | 1040 | 1122 | 1400 |

L(mm) | 1040 | 1122 | 1400 |

Layers Available | 5 | 5 | 5 |

Options:

ATEX version

Use in a potentially explosive plant environment.

Bouncing ball cleaning

Use with grainy products. There are balls located between one perforated floor and the screen fabric, which strike the screen fabric from below.

Brush cleaning

Use with crystalline or spherical products. Rotation under the screen.

Ultrasonic cleaning

Use in the ultrafine mesh range. The ultrasound is input into the screen using resonators.

Air cleaning

Use with sticky products. Air blowing out of rotating nozzle arms clears the screen fabric.

Lifting devices

Quicker access to the screening inserts.

Hygienic design

Machines are available with a high-quality "pharmaceutical finish".

Air brush cleaning

Use with greasy or electrostatically charged products.

Special outlets

Individual adaptation to upstream or downstream machinery.

Hot Tags: lactose tumbler screening machine, manufacturers, suppliers, used, for sale,