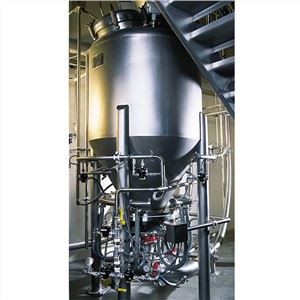

High Efficiency Pneumatic Air Jet Mixer/Airflow Blender

The working principle of QM series airflow mixer The compressed air station supplies air, and the airflow enters the silo through the nozzle of the mixing head in a pulsed manner. The compressed air spirals up along the conical wall of the conical discharge valve. The spiral rises and expands....

The working principle of QM series airflow mixer

The compressed air station supplies air, and the airflow enters the silo through the nozzle of the mixing head in a pulsed manner. The compressed air spirals up along the conical wall of the conical discharge valve. The spiral rises and expands. After the compressed air expands to a certain extent, the material settles down, and a pulse mixing process is completed.

After the end of one pulse, pause for a fixed time (adjustable) and start the mixing of the second pulse, and cycle operations in turn. The pulsed compressed gas drives the material to make the material roll over (there are also diffusion mixing, convective mixing or mobile mixing, among which convective mixing Or mobile mixing plays a major role) so that the material is evenly mixed. The mixed exhaust gas is treated by the upper filter and then discharged back to the atmosphere or recycled (protective gas such as nitrogen).

The Specification for QM Airflow Mixer

Ten product advantages of QM series airflow mixer

в‘ Fully airtight mixing: both feeding and discharging are in-line closed system, no dust leakage

The fully enclosed mixing scene reduces environmental (dust) pollution, does not require additional dust removal equipment, saves production workshop space, and greatly changes the operating environment. The editor thinks that this alone will make many manufacturers choose it.

в‘Ұ Large capacity: The capacity of the equipment ranges from tens of liters to tens of cubic meters, and the production capacity is large.

Due to the relatively small capacity of the previous mixer, the product delivery time was extended. Today's high-capacity device addresses these common problems.

в‘ұ Low energy consumption: the unit energy consumption is about 30%~50% of the mechanical mixer

в‘Ә High mixing efficiency: the mixing of large batches of materials can be completed within 3~15 minutes, CV<5%

⑤ No dead angle design: no concave round holes, inner corner residues, etc.

в‘Ө Reliable operation: There are no moving parts inside the silo body, and the maintenance work is very little.

⑦ Low pollution risk: There are no mechanical rotating parts in the mixer, no rotating shaft, shaft seal and lubricating oil, and no pollution risk.

⑧ Low breakage rate: no stirring parts, extremely low shear force, can effectively protect the crystal form of the material, and the material breakage rate is less than 0.1%.

в‘Ё Aseptic mixing: CIP cleaning, in line with GMP requirements; intelligent production.

It is precisely because of the aseptic design of the airflow mixer that it is widely used in the pharmaceutical field. Because the equipment uses the energy of the airflow to drive the powder to move and boil in the container, so that the powder is mixed evenly, so the equipment has no external power system. It does not require movement or moving parts, the equipment has a large effective volume, and is very easy to maintain and clean.

в‘© Flexibility: The user can adjust the air pressure, pulse time and pulse number according to the material characteristics to achieve the best mixing effect.

At the same time, this equipment has no wear and tear on the stirring unit and blades, which greatly improves the life of the mixer, and the mixing effect is controlled by the duration and frequency of the high-pressure air pulse, as well as the pressure and volume of the high-pressure air. In addition, the airflow mixer can integrate the conveying function, suck the materials to be mixed into the mixing bin, and can also press the mixed materials to the designated location; it can be used together with the upstream batching system and the downstream packaging line to form a complete Powder production system.

Highlights of QM Series Air Mixer

в‘ Mixer

The heart of the equipment is the mixing chamber, which takes only a few minutes to meet the quality requirements and obtain a high-quality final mixture.

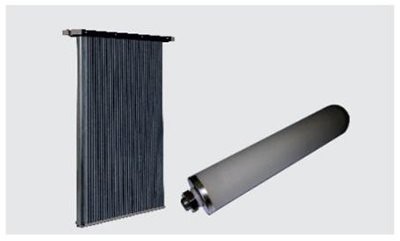

в‘Ұ Sampler

в‘ұ Cleaning ball

в‘Ә Liquid material nozzle

⑤ Titanium filter element

QM series airflow mixer application industry

In addition to the pharmaceutical industry mentioned above, this equipment can also be used in new lithium battery materials, ink coatings, pesticides, silicones, dyes and pigments, food additives, feed and oilfield chemicals industries. Industries like dyes and pigments, pharmaceuticals, and food additives all require a fully enclosed, sterile production environment. This airflow mixer from Navector (Shanghai) Screening Technology Co.,Ltd. is a perfect match and has more advantages. It integrates the shortcomings of current mixing equipment and responds to environmental protection policies. It is the first choice for essential mixing equipment.

Hot Tags: high efficiency pneumatic air jet mixer/airflow blender, manufacturers, suppliers, used, for sale,