Modified Starch Tumbler Screening Machine

Navector tumbler screen machine is used for bulk material grading, safety screening, and dedusting in all industrial sectors. They are particularly well-suited to the fine and extremely fine screening of dry bulk materials and precise grading with up to 6 particle sizes.

Tapioca Starch tumbler screening machine

Navector tumbler screen machine is used for bulk material grading, safety screening, and dedusting in all industrial sectors. They are particularly well-suited to the fine and extremely fine screening of dry bulk materials and precise grading with up to 6 particle sizes. The NAVECTOR NTS tumbler screen system features a range of customization options designed to meet extremely demanding requirements, as well as a broad variety of additional equipment options: Among these, the number of available screen cleaning systems is particularly worth mentioning, with balls, brushes, ultrasonic, and various combinations being of these options are available to prevent blinding and maintain efficient screening.

Tumbler Screener Description

Tumbler sieve is a kind of evolving from artificial screen. The movement of circular motion and toss (upward parabolic movement) are fully embodied. By adjusting the Radial angle and Tangential angle to change the amplitude of circular motion and toss. Advanced technology and design for better performance in round screen !The motion of tumbler sieve is double pendulum movement that generated by ordinary vertical motor drives eccentric wheel. The material forms a regular gradually grounding parabolic motion by adjusting the radial angle and tangential angle.

Screening Features

вҖў Modular, self-centering and expandable design

вҖў Up to 7 separations simultaneously on each machine

вҖў Slow speed and three-dimensional motion for optimal screening

вҖў Delivered ready to operate and optimized for each product (Plug & Play)

вҖў Up to 100% availability in 24 h operation

вҖў Low acceleration and low maintenance requirements, no product degradation

вҖў Dustproof, CE compliant, FDA approved rubber and plastic materials

вҖў Stainless steel 1.4301 intermediate rings and screen frame are standard

вҖў Very competitively priced with short delivery times

Tumbler Screening Machine Data Sheet

Feed Sizes | 20 Ојm вҖ“ 20 mm |

Feed Rates | 1 kg/h вҖ“ 50.000 kg/h |

Bulk Densities | 20 вҖ“ 10.000 g/l |

Mesh Openings | 20 Ојm вҖ“ 20 mm |

Screens Usable | Stainless steel wire or perforated plates |

No. of Decks | 1 вҖ“ 5 |

Mesh Cleaning | Jumping balls/rings, Rotating brush, Ultrasound |

Speed Range | 180 вҖ“ 280 minвҖ“1 |

Screen Movement | 3-dimensional, settable |

Acceleration | 1.3 вҖ“ 1.8 g / 60 вҖ“ 80 mm horizontal & 5 вҖ“ 40 mm vertical |

Materials | Carbon steel, stainless steels 304/316 |

Machine Surface Treatment | Painted, brushed or mirror polished |

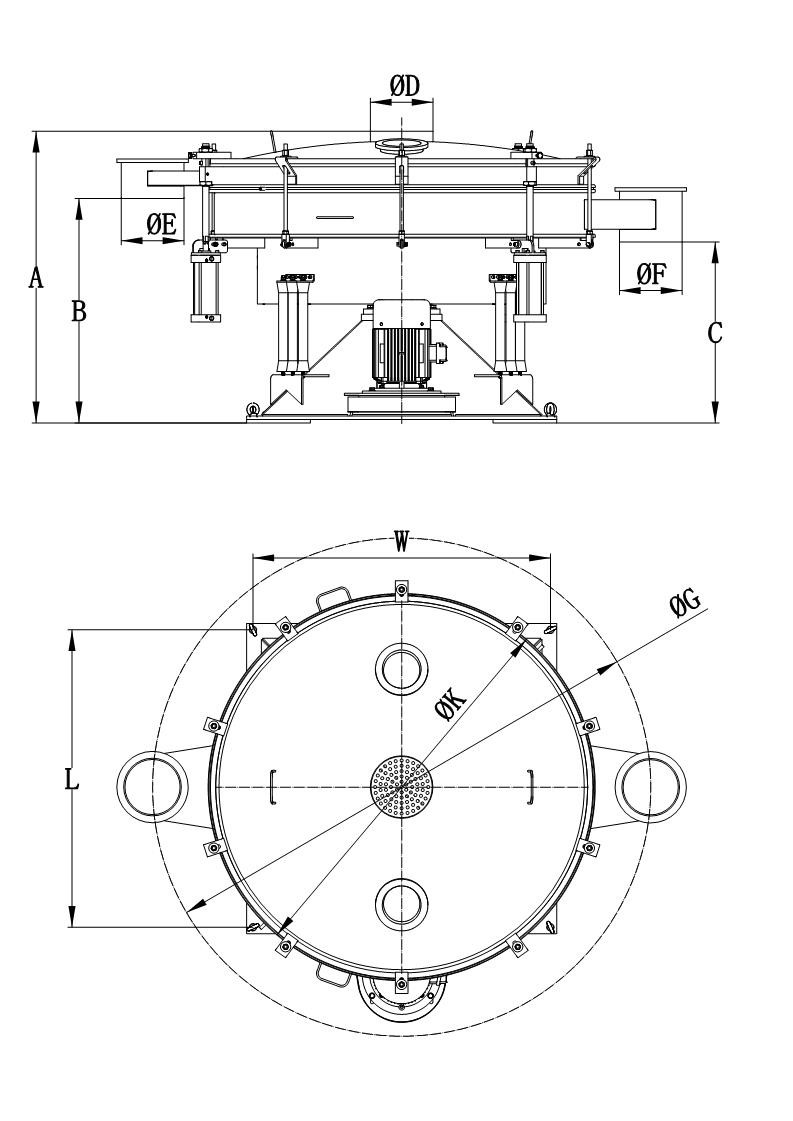

Tumbler Screener Parameters

MODEL SIZE | NTS1200 | NTS1500 | NTS1800 |

Screening area (mВІ) | 1.13 | 1.76 | 2.54 |

Diameter (mm) Гҳ | 1200 | 1500 | 1800 |

Motor power (kW) | 1.1KW | 4KW | 4KW |

Weight (kg): | 930вҖ“1120 | 1080вҖ“1450 | 1250-1760 |

A(mm) | 1236 | 1457 | 1500 |

B(mm) | 904 | 1132 | 1132 |

C(mm) | 757 | 950 | 950 |

D(mm) | ПҶ250 | ПҶ250 | ПҶ300 |

E(mm) | ПҶ200 | ПҶ200 | ПҶ300 |

F(mm) | ПҶ200 | ПҶ200 | ПҶ300 |

G(mm) | 1574 | 1940 | 2334 |

K(mm) | 1210 | 1517 | 1817 |

W(mm) | 1040 | 1122 | 1400 |

L(mm) | 1040 | 1122 | 1400 |

Layers Available | 5 | 5 | 5 |

Options:

ATEX version

Use in a potentially explosive plant environment.

Bouncing ball cleaning

Use with grainy products. There are balls located between one perforated floor and the screen fabric, which strike the screen fabric from below.

Brush cleaning

Use with crystalline or spherical products. Rotation under the screen.

Ultrasonic cleaning

Use in the ultrafine mesh range. The ultrasound is input into the screen using resonators.

Air cleaning

Use with sticky products. Air blowing out of rotating nozzle arms clears the screen fabric.

Lifting devices

Quicker access to the screening inserts.

Hygienic design

Machines are available with a high-quality "pharmaceutical finish".

Air brush cleaning

Use with greasy or electrostatically charged products.

Special outlets

Individual adaptation to upstream or downstream machinery.

Hot Tags: modified starch tumbler screening machine, manufacturers, suppliers, used, for sale,