Powder Sieving System For Additive Powder Metallurgy

Sieving of various powdered materials is carried out using mechanical sifters (sieve machines). For sieving powders with small particle sizes (20-500 碌m), machines with round sieves and three-dimensional sieve movement are often used. Two types of sieving machines are commonly used in modern...

Sieving of various powdered materials is carried out using mechanical sifters (sieve machines).聽For sieving powders with small particle sizes (20-500 碌m), machines with round sieves and three-dimensional sieve movement are often used.

Two types of sieving machines are commonly used in modern practice:

1. Periodic action.聽It is usually used in laboratories.聽After sieving, the material remaining above each of the sieves is removed manually.

2. Continuous action.聽The sieves move in such a way that they force the material to move on them from the center (place of supply) to the periphery, and gatherings are located on the periphery of the sieve.聽While moving from the center to the periphery, the fine fraction passes through the grid, the larger one remains above the grid and goes to the exit.聽By adjusting the sieve, it is possible to combine the movement of the powder from the center to the periphery and in a circle, at certain settings the powder begins to move towards the center from the periphery.

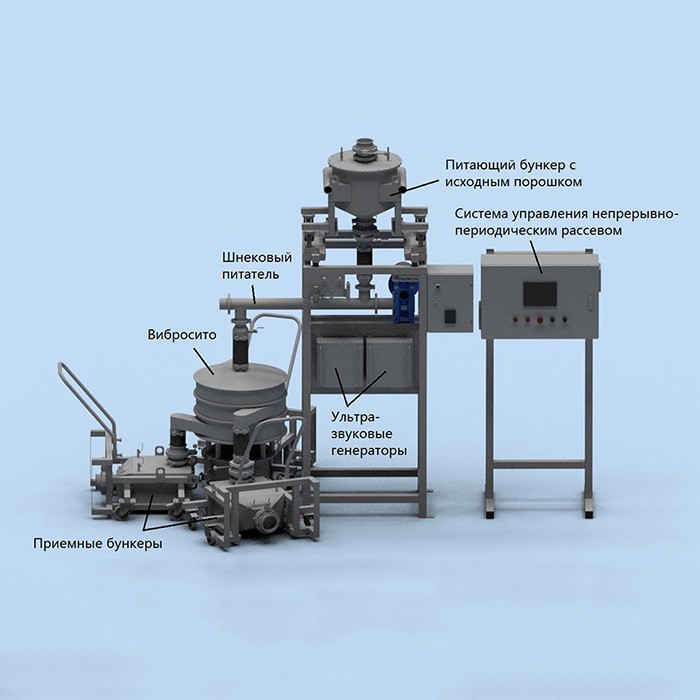

Process control system for continuous-batch sieving

The oscillations of such screens are usually generated by an electric drive with an eccentric, but can be created by both piezoelectric and electromagnetic drives. Ultrasound can be applied to the sieves to improve sieving efficiency.

When sifting powders with a fine average particle size, it becomes difficult to select the optimal trajectory of particle motion. If the powder moves quickly to the periphery, then it does not have time to be sieved and part of the fine powder does not pass through the sieve and goes to the gathering. If the speed of the powder from the center to the periphery is low, then part of the powder constantly remains on the sieve. When changing the density of the powder and the particle size, fine mechanical adjustment of the sieve machine is required.

Scheme of a sieving plant for three fractions, operating in a continuous-periodic mode.聽The unit is equipped with an ultrasonic assist system and a screw feeder.

To solve this problem, significantly increase productivity and simplify the setting of sieving machines, Navector offers sieving plants using a continuous-periodic sieving method.聽Also, using the control cabinets and supply systems manufactured by our company, it is possible to upgrade the customer's sieving systems to work according to the continuous-periodic method.聽The sieving system equipped in this way operates in two periodically changing modes:

1. Rassev.聽The machine is configured so that the powder does not leave the sieve and constantly moves on it in a circle for as long as necessary to screen out the fine fraction with the desired yield.

2. Powder drop.聽The powder quickly moves to the periphery and is thrown off the sieve.聽Used to dump coarse powder.

3. See Video

Working Features:

1.The control system automatically controls the speed of rotation of the eccentric (including the stop of the drive), the direction of rotation of the eccentric, the operation of ultrasonic generators, the feeder that supplies the classified product.

2.Switching from one mode to another is carried out by changing the direction of rotation of the eccentric (vibration drive) of the sieve.聽But it can also be achieved by changing the rotational speed, switching on and off ultrasonic assistance, for non-round sieves by changing the angle of the sieve.

3.The supply of powder to the sieve stops some time before the end of the sieving mode.聽But in a simplified version, the feed can be continuous, and the decrease in efficiency due to the ingress of fine powder during discharge to the gathering will be compensated by a higher classification efficiency in the sieving mode.

4.The alternation of sieving and dumping modes is carried out automatically by the control system.

Schemes of powder movement on round sieves using standard sieving methods:

Powder movement pattern when using the continuous-periodic sieving method with the Navector control system (the first and second powder movement patterns alternate sequentially and are set automatically):

Hot Tags: 3D printing Screen machine, Additive Powder Screening, Metal powder sifting, manufacturers, suppliers, used, for sale,