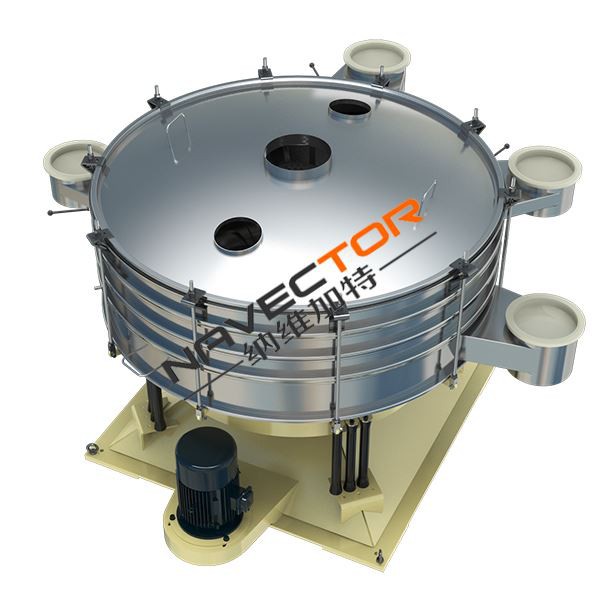

鈥婽he circular vibrating screen uses an upright motor as its main excitation source. At the same time, eccentric weights are installed at the upper and lower ends of the motor to convert the rotary motion of the motor into horizontal, inclined and vertical three-dimensional motion.

鈥婽he circular vibrating screen is a new type of screening equipment. Its working principle is to form a certain angle through the eccentric weights at the upper and lower ends of the vibration motor, so that the screen body drives the screen surface to make three-dimensional movements of horizontal, vertical and tilt.

This kind of failure occurs because the strength of the screen box is not enough, so that not only the running trajectory is abnormal, but also the screening accuracy is not the same.

鈥婦uring the installation of the new linear vibrating screen, it must be installed according to the normal installation procedure.

鈥婽here are many factors to consider when choosing a vibrating screen. Some customers may not know much about how to choose a vibrating screen.

鈥婭f you want to make the vibrating screen longer, the maintenance of the vibrating screen must be done well. Then to do the maintenance of the vibrating screen, we need to know which parts of the vibrating screen are easily damaged.

鈥媀ibrating screen replacement is one of the most common problems for customers who use vibration. Whether the screen is damaged for a long time or the material is replaced, replacing the screen is a necessary operation.

鈥婽he production capacity of the vibrating screen is usually a matter that everyone is more concerned about in industrial production.

鈥婼wing screens rely on high-frequency vibration to achieve material screening and particle classification. Therefore, swing screens are used in many fields such as chemical industry, feed, fertilizer, and food.

鈥婽he vibrating screen is a screening device that is sieved by the vibration of the motor body by the excitation force generated by the vibration motor.