Dense-phase Pneumatic Conveying Machine

Dense phase transport, also known as airflow transport, utilizes the energy of the airflow to transport particulate material along the airflow direction in a closed duct. It is a specific application of fluidization technology. The pneumatic conveying device is simple in structure, easy to...

Dense phase transport, also known as airflow transport, utilizes the energy of the airflow to transport particulate material along the airflow direction in a closed duct. It is a specific application of fluidization technology. The pneumatic conveying device is simple in structure, easy to operate, and can be used for horizontal, Vertical or oblique transport, physical or chemical operations such as heating, cooling, drying and gas grading of materials can be carried out simultaneously during transport. Material which has a lot of water content, and it has adhesiveness or materials which are easy to generate static electricity during high-speed movement are not suitable for pneumatic conveying.

Features For Dense Phase Pneumatic Conveyor

в—Џ The powder-gas mixing ratio is large, the mixing ratio of positive pressure dense phase conveying is 1:60, and the mixing ratio of positive pressure dilute phase conveying is 1-10.

в—Џ Low conveying speed, little damage to material particles.

в—Џ Conveying capacity up to 20T/h.

в—Џ The energy consumption is small, the gas contained in the powder is small, it is easy to realize the separation of powder and gas, the configuration of the transportation pipeline is flexible, and the production process is more reasonable.

в—Џ Few moving parts, closed conveying system, no dust.

в—Џ Can realize one-to-one or one-to-multipoint delivery.

в—Џ Integral 304 material or 316L material production, no dead corner, can be washed.

в—Џ The control system can be automated, but has high requirements for various electrical components.

в—Џ The working pressure is high, so long-distance transportation can be realized; the use of booster can realize ultra-long-distance transportation.

Flow Rate

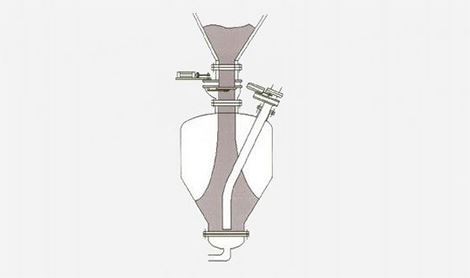

| Feeding stage: When the feed valve is opened, the material is free to fall into the pump body. When the rising material in the pump body touches the level gauge, the level meter sends a full signal, and the feed is automatically closed to complete the feed.

|

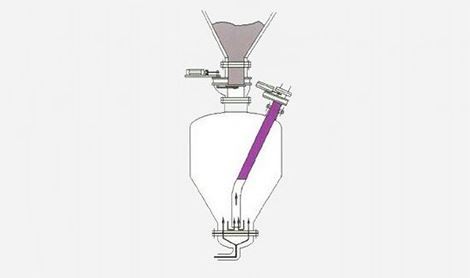

Fluidization pressurization stage: The intake valve is automatically opened, and the compressed air enters the bottom of the pump body and diffuses through the fluidized bed. At the same time as the material is fully fluidized, the gas in the pump rises.

|

|

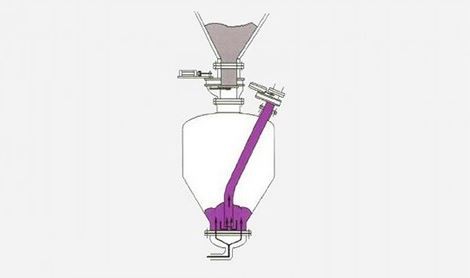

| Conveying stage: When the pressure in the pump reaches a fixed value, the pressure sensor sends a signal, the discharge valve automatically opens, the fluidization of the material on the fluidized bed enhances the delivery, and the material in the pump gradually decreases. During this process, the material on the fluidized bed is always at Transported while fluidizing.

|

Purge stage: When the material in the pump is delivered and the pressure drops to the resistance of the pipeline, the indicator light signals, the ventilation continues for a fixed time, the compressed air sweeps the pipeline, then the intake valve closes, asks the separation time, closes the discharge valve, and opens the inlet valve. , complete a delivery cycle.

|

|

On-site photos

Dense-phase pneumatic conveying @2tph, Chicken powder conveying

Dense-phase pneumatic conveying @Maltose, 10tph

Positive pressure conveying equipment @Sodium Suffocate Powder, 10tph

Refrence list for Dense phase pneumatic conveyor

| Country | Customer name | Description | Product Handle |

Shanghai, China | Shanghai Baosteel | NPPC-150,4t/h | Quick lime powder |

Shanghai, China | Yihai kerry | NPPC-150, 12t/h | Granulated Sugar |

Jiangsu, China | Jiangsu Hongda New Material Co.,Ltd | 16t/h | silicon powder |

China | "A national corp." | NPPC-250,10t/h | limestone powder |

Shandong, China | LUXI Chemical | NPPC-150,7~10t/h | urea |

Rayong, Thailand | SCG chemical | NPPC-150,5T/h | PE |

Hot Tags: dense-phase pneumatic conveying machine, Dense phase Pneumatic conveyor, Positive pressure feeder, pneumatic conveying system, pneumatic feeding system, manufacturers, suppliers, used, for sale,