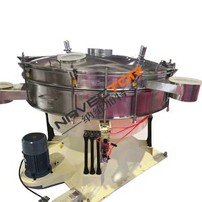

Influence Of The Surface Length Of Ultrasonic Vibrating Screen On The Screening Effect

What is the relationship between the surface length of the ultrasonic vibrating screen and the screening effect? Let's explain it in detail below, let's take a look! The longer the surface of the ultrasonic vibrating screen, the longer the material will be screened on the screen, and the screening accuracy The higher. There is a direct relationship between the screening time (or screening length) and the fineness of the screening.

The width of the screen appearance of the ultrasonic vibrating screen must also be appropriate, and it must be proportional to the length of the screen appearance. When the screen loads are equal, the screen width is small and the length is large, and the data layer on the screen surface is thick. It is difficult for the fine particles to approach the screen surface and pass through the screen holes. On the contrary, when the width of the screen surface is large and the length is small, the thickness of the material layer is surely reduced, and the fine particles are easy to approach the screen surface.

However, because the residence time of the particles on the surface of the sieve is short, the possibility of the material passing through the sieve holes is small, and the screening power is small. It will inevitably decrease. In other words, the screen surface width coefficient of the linear screen determines the screening capacity of the vibrating screen, and the reasonable length determines the standard of material fineness.

In addition to the selection of the power of the vibration motor, the adjustment of the eccentric component of the vibration motor, the characteristics of the material itself, and the regularity of the boring moisture, there are many factors that affect the power of the ultrasonic vibration screen. And the size of the material to be screened. Make a big impact.

Therefore, if the screening time is too long, it is not necessary to thoroughly clean, and the information needs to be summarized and considered. Because when the screen angle is horizontal, in order to add the screen moment, only the screen length is added. The screen surface is too long, not good, plant space is wasted, the screen structure is cumbersome, the screening power is not high, and the screen length must be appropriate.

As long as the screen is operated under high load, in order to ensure high screening power, it is sometimes advantageous to appropriately add the length of the screen if the configuration conditions agree. For a certain material, the productivity (output) of the ultrasonic vibrating screen depends primarily on the screen width, and the screening accuracy depends primarily on the screen length.

As a result, most easily sievable particles are sieved out, leaving some difficult to sieving particles. Although added all the time, the sieving fineness of the ultrasonic vibration sieve is higher, which is satisfactory for sieving the fineness of the powder particles.